Cleanroom Packaging

Competence profile

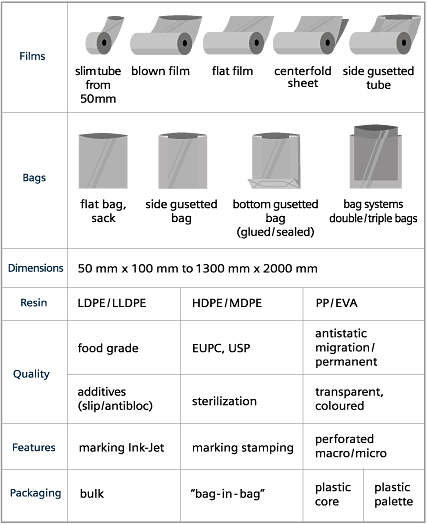

- Cleanroom packaging materials

- Cleanroom films, Cleanroom bags

- Cleanroom specialities:

bag-systems, inliner with round bottom,

side gusseted bags, - Indivicual packaging specification

- qualified product development and

project management - Quality and Efficiency

- we create individual quality- and logistic systems

togehter with our customers - TESTED DEVICE

Protection against contamination

- Cleanroom packaging avoids the risk of cross contamination

- Packaging materials need to meet the same quality requirements like the finished products

- This is evident all over the cleanroom-value-chain from starting materials via components up to consumer products

- Cleanliness and hygiene during the packaging process

- Markets: Pharmaceuticals, Medical Device Industry, Chemicals, Automotive,(Micro) Electronics, Food, Optics

- Products: API, Tubes, Implants, Equipment, Valves, Filters, Pumps, Instruments, Packaging f.e. Bottles, Closures, Fixings, Pumps, cleanroom consumables

Press release on STRUBL CLEANROOMPACKAGING

CLEANROOM VALUE CHAIN

GMP Principles

- Cleanroomproduction ISO 14644-1, class 7 - 9)

- Hygienemanagement / Pestcontrol / HACCP- Principles

- GMP-related process design, documentation, trainingsg

- Total Traceability / Validation / Qualification

- Starting materials with EP / USP / FDA

- Kontaminationsfreie Verpackung („Bag-in-Bag“), Prüfzertifikate

- ISO 9001:2008, EC-Fehlerbewertungslisten, In-Prozeß-Kontrolle

GMP related Process

- Blown Film Extrusion (Mono and Coex)

- Converting

- manual Converting for specialities

- Packaging ("bag-in-bag")

- Release

Detailed Informations

|

|

|

|

|

Cleanroom bags

Application

- Protect against contamination inside the cleanroom value chain

- Applicable for cleanrooms up to ISO 7 DIN EN ISO 14644-1

- transparent, with additives for easy open, sealable

- for packaging of smal lots of cleanroom products

Specification

- Material: LDPE 100 my, with Additiven (slip, antiblock), foodgrade EU 10/2011

- features: bottom seal, cleanroomquality, transparent

- Packaging: cleanroom approved = "bag-in-bag" (doublepacked in PE-film)

| Dimension (widht x length) | Packaging | Price per Unit |

| 100 x 200 mm | 1.000 pcs. / carton box / 1 unit | EUR 239,00 |

| 200 x 300 mm | 500 pcs. / carton box / 1 unit | EUR 189,00 |

| 300 x 500 mm | 500 pcs. / carton box / 1 unit | EUR 239,00 |

| 400 x 600 mm | 250 pcs. / carton box / 1 unit | EUR 159,00 |

| 500 x 700 mm | 250 pcs. / carton box / 1 unit | EUR 177,00 |

| 600 x 800 mm | 250 pcs. / carton box / 1 unit | EUR 219,00 |

| 1.000 x 1.200 mm | 100 pcs. / carton box / 1 unit | EUR 209,00 |

On special request, all products can be produced realted to customer specifications f.e. antistatic, EP / USP conformity

For detailed questions just contact our product management:

- Mr. Jörg Kommallein - Tel: 09129 / 9035-75 - Fax: 09129 / 9035-49

joerg.kommallein@strubl.de

Cleanroom films

Application

- Protect against contamination inside the cleanroom value chain

- Applicable for cleanrooms up to ISO 7 DIN EN ISO 14644-1

- transparent, with additives for easy open, sealable

- for packaging of smal lots of cleanroom products

Spezifikation Schlauchfolie

- Material: LDPE 100 my, with Additiven (slip, antiblock), foodgrade EU 10/2011

- features: bottom seal, cleanroomquality, transparent

- Packaging: cleanroom approved = "bag-in-bag" (doublepacked in PE-film)

| Dimenstion (width) | Packaging | Price per unit |

| 50 mm | 250 mtr. / Rolle | on requeste |

| 100 mm | 250 mtr. / Rolle | on request |

| 200 mm | 250 mtr. / Rolle | on request |

| 300 mm | 250 mtr. / Rolle | on request |

| 400 mm | 200 mtr. / Rolle | on request |

| 500 mm | 200 mtr. / Rolle | on request |

| 600 mm | 150 mtr. / Rolle | on request |

| 1.000 mm | 150 mtr. / Rolle | on request |

On special request, all products can be produced realted to customer specifications f.e. antistatic, EP / USP conformity

For detailed questions just contact our product management:

- Mr. Jörg Kommallein - Tel: 09129 / 9035-75 - Fax: 09129 / 9035-49

joerg.kommallein@strubl.de